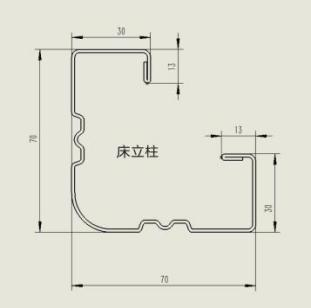

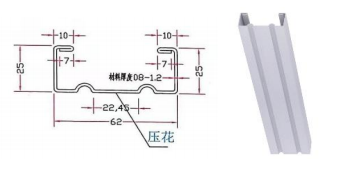

1.Open Bed Columns: High-quality rolled steel plates are used in a single forming process to create open profiles. This allows for double-sided spray painting, extending the column's service life. The finished dimensions are ≥70mm x 70mm, with a thickness of ≥1.2mm. To prevent injuries from steel edges, the inner edges of the steel plate are pressed against the edges, with a ≥5mm bend. Each end has an outer width of ≥30mm and an inner width of ≥13mm. To provide enhanced torsion resistance and durability, the columns are equipped with ≥4 concave and convex ribs on both sides for increased durability. The upper and lower legs of the columns are covered with high-quality PP plastic, which securely fits the legs for a secure and durable finish. The bidding documents must provide actual measurement photos of the bed columns to prove that the physical requirements are met. The facade size after forming is ≥70mm×70mm, the thickness is ≥1.2mm, and the outer side of the bent edges at both ends has an outer width of ≥30mm and an inner width of ≥13mm.

|

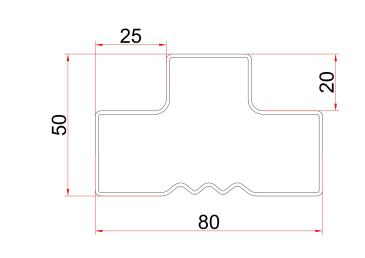

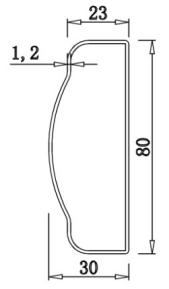

2.Convex Bed Center Post: Convex profiles are formed from high-quality rolled steel plate in a single pass through a forming machine. The finished vertical dimensions are ≥80mm × 50mm × 30mm, with a thickness of ≥1.2mm. The front of the center post is equipped with ≥2 concave and convex reinforcement ribs for enhanced lifespan. The spaces between the center posts are constructed from high-quality square tubing ≥25mm × 50mm, with a thickness of ≥1.2mm. The upper guardrail is constructed from high-quality round tubing ≥22mm, with a thickness of ≥1.0mm. The lower insert is constructed from ≥17mm melamine-impregnated double-faced MDF. The upper and lower center posts are covered with high-quality PP plastic foot covers, which should be tightly bonded to the post for durability. Bidding documents must include actual measurement photos of the bed center post to verify that these dimensions are met. The finished vertical dimensions are ≥80mm × 50mm × 30mm, with a thickness of ≥1.2mm.

|

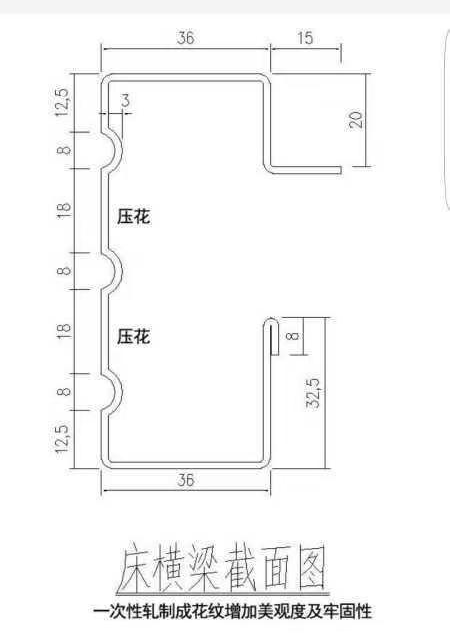

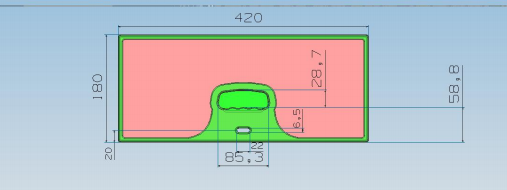

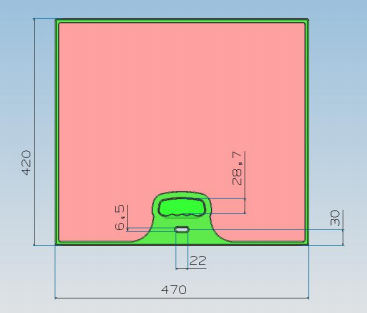

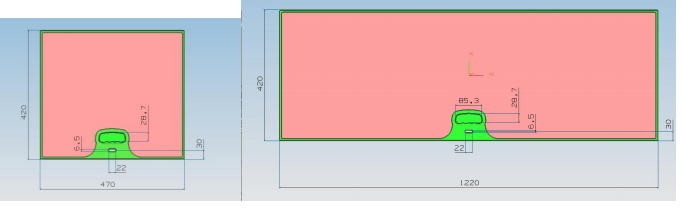

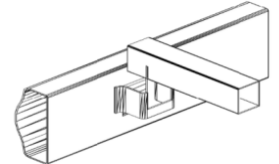

3.Opening side crossbeam: This profile is made of cold-rolled steel plate rolled on a specialized forming line. Its vertical profile is hollow and shaped. The finished vertical dimensions are ≥85mm*36mm. The front face has at least two ≥8mm inward-facing reinforcing ribs. An opening is reserved on the inner side, with a welded iron plate to facilitate the installation of the bed rail's receiving clips, preventing them from falling off. The opening of the bed rail is bent back at the upper end to close it, effectively protecting students. The material thickness is ≥1.2mm. (A slot must be installed in the center front of the metal bed rail to facilitate the insertion of student ID cards.) (Note: Bidding documents must include actual measurement photos of the metal bed rail to verify that it meets the requirements. The finished vertical dimensions are ≥85mm*36mm. The front face has at least two ≥8mm inward-facing reinforcing ribs.)

|

|

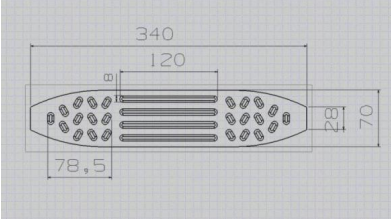

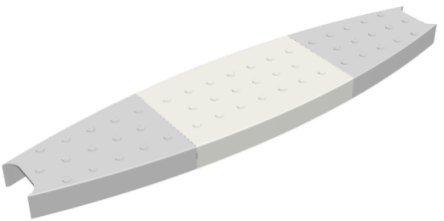

4.The steps are made of 1.2mm thick cold-rolled steel plates punched into a ship shape in one step. The overall dimensions are: length 340×width 70×thickness 25mm. There are anti-slip convex points on the surface (4 convex ribs in the middle) to increase the aesthetics and safety.

|

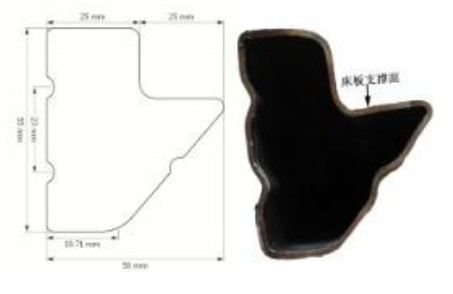

5.Steel support for decking: Use 4 high-quality cold-rolled square tubes of 30mm*20*1.2mm. The installation adopts embedded snap-on connection, which is convenient, safe and reliable. (See attached picture). The 30*20 square tube should comply with GB/T 3325-2017 "General Technical Conditions for Metal Furniture", QB/T 3827-1999 "Test Method for Corrosion Resistance of Metal Coatings and Chemically Treated Layers of Light Industrial Products - Acetic Acid Salt Spray Test (ASS) Method", QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings of Light Industrial Products", GB/T 1741-2020 "Determination of Fungal Resistance of Paint Films" testing standards, the test content includes at least: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, specified plastic extension strength Rp0.2 ≥ 300MPa. Bed board: It should be made of high-quality domestic fir wood, ≥15mm thick, dried and polished on both sides. The joint gap should be less than 5mm, and each bed board should not be composed of more than 8 wooden boards. The back of the bed board needs to be reinforced with 4 25*35mm full-size solid wood square bars. Chinese fir bed boards should comply with the testing standards of JC/T2039-2010 "Antibacterial and Mildew-Resistant Wood Decorative Panels", GB/T 3324-2017 "General Technical Conditions for Wooden Furniture", and GB 18580-2017 "Interior Decoration and Renovation Materials - Formaldehyde Emission Limits in Artificial Boards and Their Products". The testing contents shall at least include: ① Formaldehyde emission ≤ 0.030 mg/m³; ② The moisture content of the wood meets the qualified requirements; ③ The appearance of wooden parts: through cracks, insect bites, rotten wood, resin sacs, knots, dead knots, holes with bark and resin channels, gum channels, and other minor material defects all meet the qualified requirements; ④ Antibacterial and mildew-proof performance (mildew-proof grade) (Aspergillus niger, Aspergillus flavus, Brassica rapa (multi-main branch spore mold), Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium officinale, Alternaria alternata) level 0 or level 1.

|

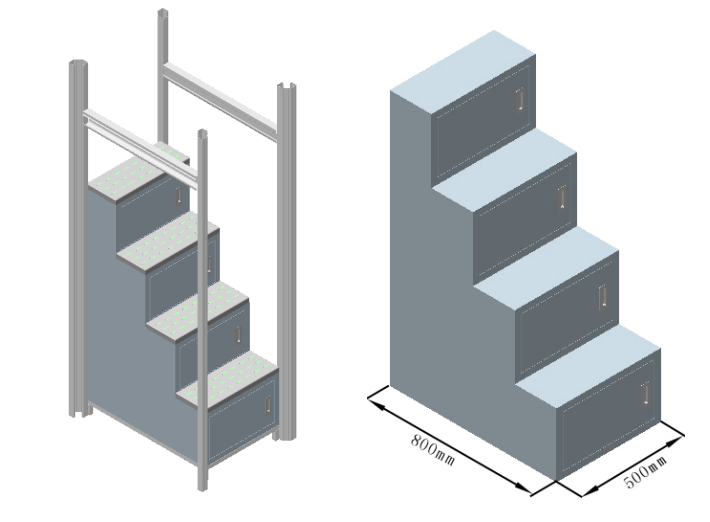

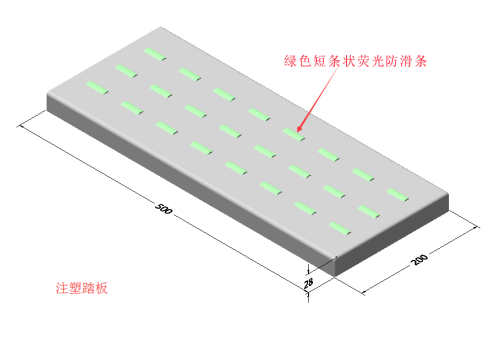

6.The staircase consists of three parts: 1. An independent four-step steel locker. All lockers are made of cold-rolled steel with a thickness of ≥0.8mm. The locker door handles are built-in handles (to prevent trouser legs from getting caught), must be equipped with door stops, and do not have locks. The top locker door is a false door (does not open), and the bottom locker has no cold-rolled steel bottom plate (use the bracket in point 3 below to place shoes as a shoe cabinet); 2. Footrests: Footrests are installed on the four steps of the locker and are hydraulically molded in one step using injection-molded PP heavy polystyrene sheets. , step specifications: 500mm*200mm*28mm, the pedals are embedded with green fluorescent anti-slip strips to facilitate students' night activities; 3. There is an 800mm*500mm bracket made of 25mm*25mm*1.3mm square tube welding under the locker, which is installed at the bottom of the four-step steel locker (10 horizontal square tubes are evenly distributed, the net height of the bottom of the bracket from the ground is 60mm, and it is equipped with plastic foot pads) to support the locker and serve as the bottom shoe rack of the locker. Foot pedals: Foot pedals are installed on the four steps of the locker. They are made of injection-molded PP heavy polystyrene sheet and hydraulically molded in one step. The step specifications are: 500mm*200mm*28mm. The pedals are embedded with green fluorescent anti-slip strips to facilitate students' night activities. The 25*25 square tubes should comply with GB/T 3325-2017 "General Technical Conditions for Metal Furniture", QB/T 3827-1999 "Test Method for Corrosion Resistance of Metal Coatings and Chemically Treated Layers of Light Industrial Products - Acetic Acid Salt Spray Test (ASS) Method", QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings on Light Industrial Products", GB/T 1741-2020 "Determination of Fungal Resistance of Paint Films" testing standards, the test content includes at least: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, specified plastic extension strength Rp0.2 ≥ 300MPa.

|

|

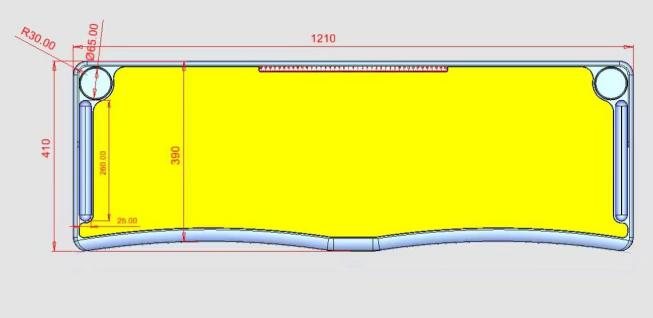

7.The tabletop measures 1210mm*410mm*18mm (±5mm for the external dimensions). Made of environmentally friendly high-density fiberboard, it features two pen holders above the tabletop. The pen holders and surrounding edges are made of PP plastic, seamlessly sealed by one-time injection molding. High-density fiberboard must comply with GB/T31765-2015, GB 18580-2017, GB/T39600-2021, GB/T42898-2023, and JC/T 2761-2023. Inspection and testing criteria include, but are not limited to: density ≥ 0.80 g/cm³; moisture content 7-12%. Internal density deviation: ±10%. Verticality ≤ 1.5. Static flexural strength ≥ 35 MPa. Elastic modulus ≥ 3500 MPa. Internal bonding strength ≥ 1.0 MPa. Thickness expansion upon water absorption ≤ 8.0%. Moisture resistance: Wet static flexural strength ≥ 20 MPa after immersion at 70°C. Formaldehyde emission: ≤0.05mg/m³. Single semi-volatile organic compound emission - dibutyl phthalate: Not detected after 14 days. Formaldehyde purification efficiency: 90%.

|

|

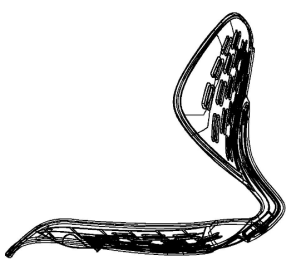

8. Table leg bracket: Made of 30mm*70*1.4mm thick oval tube, it is bent in one step by a fully automatic core-pulling tube bending machine. The bends are smooth and rounded without grooves, ensuring firmness and beauty. The steel pipes used should comply with GB/T 3325-2017 "General Technical Conditions for Metal Furniture", QB/T 3827-1999 "Test Method for Corrosion Resistance of Metal Coatings and Chemically Treated Layers on Light Industrial Products - Acetic Acid Salt Spray Test (ASS) Method", QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings on Light Industrial Products", GB/T 1741-2020 "Determination of Fungal Resistance of Paint Films" standard, the test content at least includes: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) level 0 or level 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metallic spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, specified plastic extension strength Rp0.2 ≥ 300MPa. Desks should comply with GB/T 3325-2017 "General Technical Requirements for Metal Furniture", QB/T 4071-2021 "Desks and Chairs", GB/T 3324-2017 "General Technical Conditions for Wooden Furniture" standard, the test content includes at least: (1) Surface physical and chemical properties: Metal spray coating has qualified impact resistance and adhesion level 0; (2) Metal spray paint (plastic) coating: Corrosion resistance (within 1000 hours, observe that there should be no bubbling outside 3mm on both sides of the scratch on the sample in the solution; after 1000 hours, check that there should be no rust, peeling, wrinkling, discoloration and loss of gloss outside 3mm on both sides of the scratch); (3) Mechanical properties: Tabletop vertical static load, tabletop vertical impact, table leg drop, tabletop horizontal static load, tabletop vertical durability are all qualified; (4) Formaldehyde emission ≤0.4mg/L; (5) The content of harmful heavy metals (soluble lead, soluble cadmium, soluble chromium, soluble mercury) is all qualified;

|

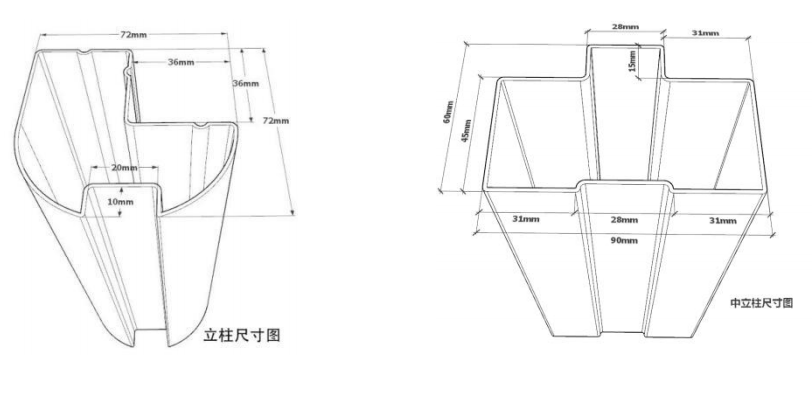

9. Closed front bed columns and center ladder rear columns: The profile tube is made of cold-rolled steel plate, formed into a closed profile in one step using a forming machine. The vertical surface is hollow and shaped, with an overall dimension of 72mm*72mm. The outer side is a 72mm diameter semi-circular arc to prevent damage. The arc has a groove in the middle, measuring 10mm*20mm after forming. The groove is installed with aluminum alloy decorative strips. Each of the three inner sides of the column has an inward concave reinforcement rib, with a thickness of 1.2mm. The center column: The vertical surface measures 90mm*60mm after forming, with a thickness of 1.2mm. The upper convex width is 28mm, and the left and right straight edges are 45mm wide. A 28mm wide concave reinforcement rib is installed on the front of the column to increase its overall strength. The closed convex tube is formed from high-quality cold-rolled steel plate in one step and cannot be formed into a right angle. The remaining columns are made of high-quality cold-rolled square tube measuring 60*60*1.2mm. Conforms to QB/T 3826-1999 and QB/T 3832-1999 standards.

|

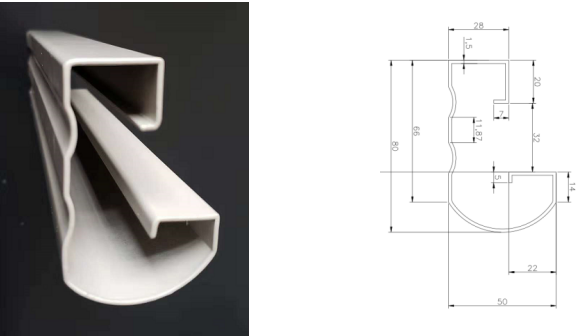

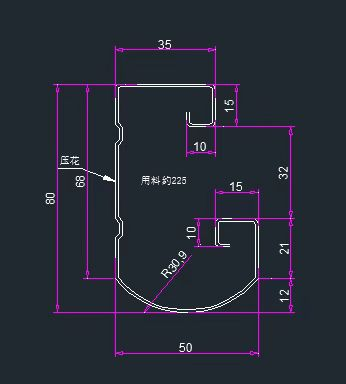

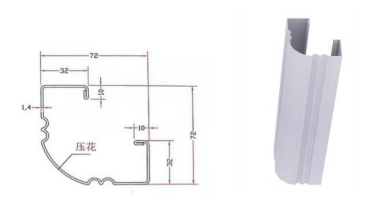

10. Open bed crossbeam: This open G-shaped profile is made from high-quality rolled steel plate using a forming machine. To ensure student safety, the crossbeam is semi-circular on the bottom and flat on the top. Both sides of the opening have a 90-degree hem of at least 5mm to protect against hand injuries. It does not use a closed tube, allowing for double-sided spray painting inside and out for a longer lifespan. The finished dimensions are 80mm narrow at the top and 28mm-50mm wide at the bottom (±1mm). This effectively supports all the bed supports, including both the steel and wooden supports. This ensures that the bed and wooden supports never become loose during use, ensuring a secure and secure fit. The front of the crossbeam must be rolled using a mold to create a wavy pattern for added strength and aesthetics. The thickness is 1.4mm (see attached image).

|

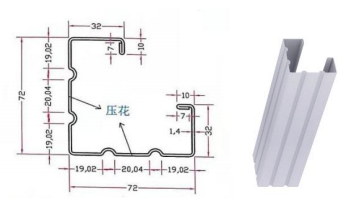

11. Open Crossbeam: The profile tube is made of high-quality cold-rolled steel plate, rolled in a single pass on a forming machine to create an open profile. This allows for double-sided spray painting, extending the lifespan of the columns. The finished dimensions are ≥80mm × 35mm top width × 50mm bottom width, with a thickness of ≥1.2mm. To enhance the columns' torsional resistance and durability, the crossbeam features two concave arc-shaped reinforcement ribs on the outside and an embossed center rib on the outside. A 15mm-wide flat surface is located beneath the crossbeam for bed support. The upper and lower ends of the inlet are double-removed to enhance the crossbeam's rigidity and prevent scratches on students. To prevent bumps, the bottom of the crossbeam features a rounded shape. Bidding documents must include actual measurement photos of the crossbeam to verify compliance. The finished dimensions are ≥80mm × 35mm top width × 50mm bottom width, with a thickness of ≥1.2mm. The bed beams should comply with GB/T 1741-2020 "Determination of mildew resistance of paint films", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", QB/T 3827-1999 "Test method for corrosion resistance of metal coatings and chemical treatment layers on light industrial products". The testing standards for the "Acetic Acid Salt Spray Test (ASS) Method" include at least the following: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungus resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, and adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, and specified plastic extension strength Rp0.2 ≥ 300MPa.

|

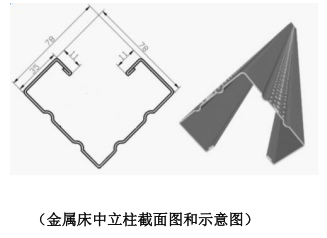

12. Open Center Bed Post: C-shaped open profiles are formed from cold-rolled steel sheets in a single step. The finished dimensions are ≥78mm*78mm*35mm. The posts must have mounting holes on the surface for bed hooks. Each side of the post must have at least two reinforcing ribs with an inward concave width of ≥7mm, with a total of ≥4 ribs. To enhance support, the C-shaped ends must be bent ≥11mm. The steel plate thickness is ≥1.2mm. (Note: The bidding documents must include measurement photos of the metal center bed posts to verify that they meet these requirements. The finished dimensions are ≥78mm*78mm*35mm. Each side must have at least two reinforcing ribs with an inward concave width of ≥7mm, and the C-shaped ends must be bent ≥11mm.)

|

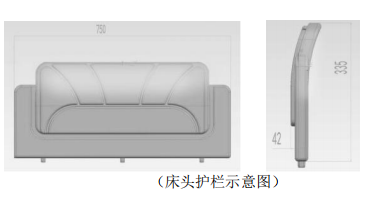

13. Headboard Specifications: 750mm long, 335mm high, 42mm thick (±5mm tolerance allowed). Made of HDPE plastic pellets, the headboard is blow-molded in two layers. The lower layer connects the uprights and short side beams. The upper layer, the backrest, features a curved design that conforms to ergonomics.

|

14. Bedside columns: The profile tube is made of cold-rolled steel plate and rolled into an open profile by a forming machine (closed tubes cannot be used) so that the product can be sprayed on both sides. The vertical size after forming is (7.2cm±0.2cm)*(7.2cm±0.2cm), and the inner side edges are pressed dead. There are two vertical inward reinforcing ribs on each side of the column, and the middle outward corner is a semicircular arc with a vertical pattern. The pattern must be formed in one step by die stamping to increase strength and aesthetics. The material thickness is ≥0.12cm (reference figure is shown below). Bed columns should comply with GB/T 1741-2020 "Determination of mildew resistance of paint films", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", and QB/T 3827-1999 "Corrosion resistance test method of metal coatings and chemical treatment layers of light industrial products The testing standards for the "Acetic Acid Salt Spray Test (ASS) Method" include at least the following: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungus resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, and adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, and specified plastic extension strength Rp0.2 ≥ 300MPa.

|

15. Bed column: The profile tube is made of cold-rolled steel plate, rolled in a single process using a forming machine to form an open profile (closed tubes are not acceptable). This allows for double-sided spray painting. The finished surface dimensions are (7.2cm ± 0.2cm) x (7.2cm ± 0.2cm), with the inner edges pressed to the sides. Each side of the column has two vertical inward reinforcing ribs, each with a vertical pattern between the two ribs. This pattern must be stamped in a single process to enhance strength and aesthetics. Material thickness must be ≥ 0.12cm (see the reference image below). The bed column should comply with the following standards: GB/T3325-2017, GB/T30789.2-2014, GB/T30789.3-2014, GB/T30789.4-2015, GB/T30789.5-2015, GB/T30789.8-2015, GB/T10125-2021, GB/T 21866-2008, HG/T 3950-2007, QB/T4767-2014, GB/T4336-2016, GB/T232-2010, GB/T19746-2018, GB/T 3075-2021. Inspection and testing items include but are not limited to: Appearance performance - Metal paint (plastic) coating: There should be no missing spraying, rust, discoloration, fading, etc. Metal Spray Paint (Plastic) Coating - Hardness: Pencil hardness H, no plastic deformation and/or cohesive failure. Impact Strength: No peeling, cracking, or wrinkling at an impact height of 400mm. Salt Bath Resistance: No blistering, rust, peeling, or wrinkling beyond 3mm on either side of the scribe line. Adhesion: Not less than Class 1. Neutral Salt Spray Test (NSS) for 120 hours, Acetic Acid Salt Spray Test (ASS) for 120 hours, Copper Accelerated Acetic Acid Salt Spray (CASS) for 120 hours: Blistering Grade (No Blistering Grade 0), Rust Grade (No Rust Grade 0), Cracking Grade (No Cracking Grade 0), Peeling Grade (No Peeling Grade 0). Peeling and Corrosion Grade around the scribe line (Corrosion Grade 1, Peeling Grade 1). Antibacterial Properties: Lactobacillus reuteri and Streptococcus pyogenes: Antibacterial Rate ≥ 99%. Antifungal Properties: Aspergillus parasiticus and Penicillium glabrata: Antifungal Performance Grade 1. Metal spray coating thickness: 60-130μm. Carbon (C), Silicon (Si), Manganese (Mn), Phosphorus (P): Carbon (C): ≤ 0.12%, Silicon (Si): ≤ 0.30%, Manganese (Mn): ≤ 0.50%, Phosphorus (P): ≤ 0.035%. Bend test: No cracks. Salt solution immersion test for 168 hours: Mass loss rate ≤ 1.0g/㎡. After 168 hours of immersion, the sample surface coating showed no corrosion. Fatigue test: 300,000 cycles: No fracture.

|

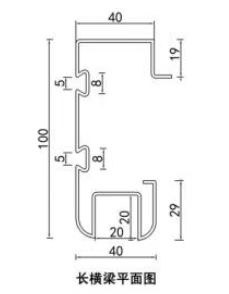

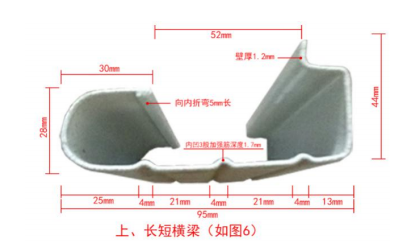

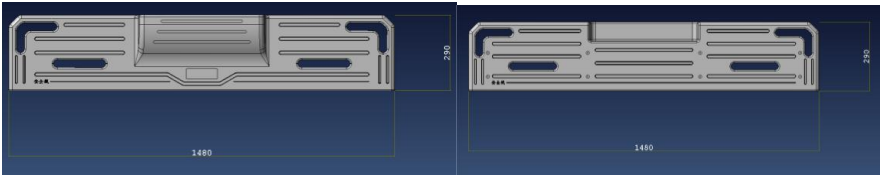

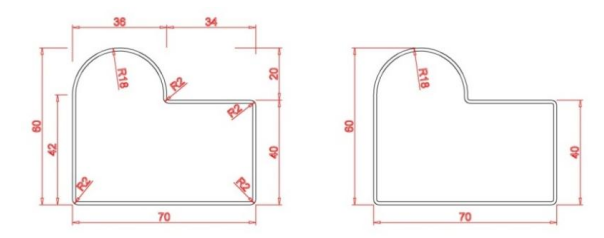

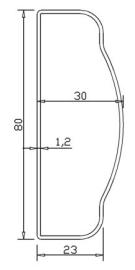

16. Long and short bed beams: Profile (9.5cm±0.2cm) × (4.4cm±0.2cm) (including protruding tongue) × ≥0.12cm. The cold-rolled plate is rolled into a special-shaped tube at one time by a forming machine (closed steel tubes cannot be used) so that the product can be sprayed on both sides inside and outside; there are three concave reinforcing ribs in the middle of the beam, which are pressurized and formed. The bottom of the beam must be arc-shaped to prevent the body from bumping into right-angled areas. A plastic steel curtain rail is added to increase user privacy. The bed beam should comply with GB/T 1741-2020 "Determination of mildew resistance of paint film", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", and QB/T 3827-1999 "Corrosion resistance test method of metal coatings and chemical treatment layers of light industrial products The Acetic Acid Salt Spray (ASS) test standard includes at least: 10 corrosion resistance and 10 protection levels in the acetic acid salt spray test (≥1200h); 0 or 1 fungal resistance (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, and Alternaria alternata); soluble heavy metal content in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, and soluble cadmium ≤ 5mg/kg; for metallic spray paint (plastic) coatings: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, and adhesion 0; and tensile strength (Rm) ≥ 300MPa, elongation (A50mm) ≤ 35%, and specified plastic extension strength (Rp0.2) ≥ 300MPa. (The reference diagram is shown below).

|

17. Lower short crossbeam and rear tie rod: Use cold-rolled steel plate, formed in a single pass through a forming machine, to form an open profile (do not use closed tubes). This allows for double-sided spray painting. The finished dimensions are (6.2cm ± 0.2cm) by (2.5cm ± 0.2cm), with a plate thickness of ≥ 0.12cm. The crossbeam has two concave reinforcing ribs running down the middle of the crossbeam. This is pressurized and features a horizontal pattern running down the middle of the ribs. This pattern must be stamped in a single pass to enhance strength and aesthetics. The lower portion of the crossbeam must be rounded to prevent collisions with right angles (see the diagram below).

|

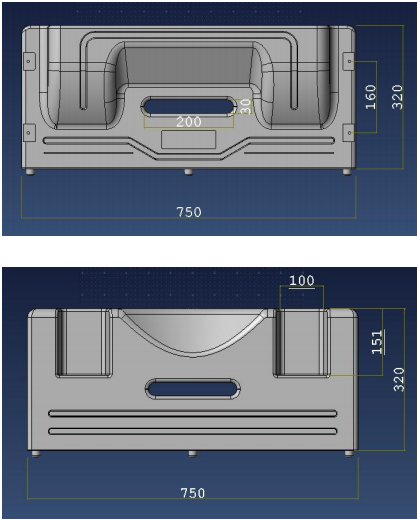

18. Bedside Guardrail: Made of HDPE high-density polyethylene plastic granules, hollow-molded using a blow mold. It is resistant to aging, wear, and stamping. It has no burrs around the sides and bottom, is smooth and safe, and meets environmental standards. Plastic masterbatch is added. Specifications: 75cm long, 32cm high, 3.2cm thick (appearance dimension deviation is ±0.2cm). A concave curve is designed in the center of the inner upper portion of the guardrail for increased student comfort. Storage platforms measuring 10cm ±0.2cm long, 6cm ±0.2cm wide, and 15cm ±0.2cm high are located on each inner side (suitable for small items such as mobile phones). An oval-shaped hole measuring 20cm ±0.2cm long and 3cm ±0.2cm high is provided in the center for ventilation. The guardrail has at least three raised points on the bottom for snapping onto the bed rails. At least two pre-buried nuts are located on each side for securing to the bed posts. (See the diagram below for reference.)

|

19. Bed Guardrail: Made of HDPE high-density polyethylene plastic granules, hollow-molded using a blow-molded mold. It is resistant to aging, wear, and impact. It has no burrs around the edges or bottom, and is smooth and safe, meeting environmental standards. Plastic masterbatch is added, and it contains no heavy metals or other toxic or hazardous substances. Specifications: 148cm long, 29cm high, 3.2cm thick (appearance dimensions allow for ±0.2cm deviation). A protruding storage platform, measuring at least 46cm long and 7cm wide, is located in the center of the guardrail (suitable for small items such as glasses and cell phones). Special-shaped holes, at least 15.5cm long, are designed on the front and back of the guardrail to serve as handrails when students climb into and out of bed. The surface is reinforced with grooves. Four holes, at least 1.9cm in diameter, are provided at the bottom for securing to the bed rail. (See the image below for reference.)

|

20. Steps: Made of PE polyethylene, the material is one-time hollow blow molding. The front edge of the step must be arc-shaped to prevent injuries. The surface of the step must have anti-slip grooves and be inlaid with eight circular luminous pieces with a diameter of 2.0cm ± 0.2cm to enhance aesthetics and safety. Step specifications: 40.8cm * 12.8cm * 3.5cm, with the overall dimensions of the step ± 0.2cm. (See the reference image below)

|

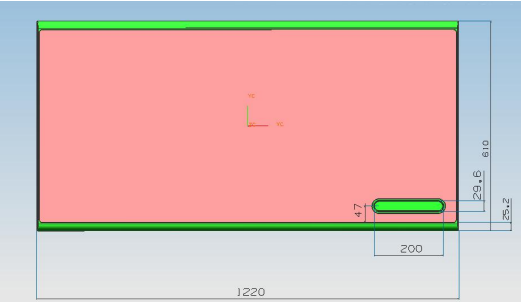

21. Writing Desk: The desk body is constructed of environmentally friendly ecological board ≥1.7cm thick, and the top panel is constructed of environmentally friendly density board ≥2.5cm thick. The top panel specifications are: (122cm ± 0.2cm) × (61cm ± 0.2cm) × (2.5cm ± 0.2cm). The environmentally friendly density board has injection-molded edges, with a slight curve at the front and back. A pen slot is located at the lower right corner of the desk. The slot measures 20.0cm ± 0.2cm in length, 2.96cm ± 0.2cm in width, and has a recessed depth of 0.7cm ± 0.2cm. The remaining panels are ≥1.7cm thick (E1 grade) solid fir core ecological board. ≥0.12cm thick PVC edge banding is applied automatically, using high-temperature granular hot-melt adhesive. The edges are sealed using an automatic edge banding machine, ensuring a secure bond, no debonding, no bubbling, and waterproofing. (See the image below for reference.)

|

22. Drawer facing: 18cm*42cm*1.8cm (±0.2cm tolerance allowed). The panel base is made of environmentally friendly E1-grade medium-density fiberboard (MDF) ≥1.8cm thick. The surface is tough, break-resistant, easy to clean, moisture-resistant, and fade-resistant. The drawer top is molded using PP injection molding with edge banding. The upper center of the door panel features a handle and keyhole, a user-friendly design with smooth edges. The remaining panels are ≥1.7cm thick (E1-grade) solid fir core eco-friendly boards. ≥0.12cm thick PVC edge banding is fully automated, using high-temperature granular hot-melt adhesive. The edges are sealed using a fully automated edge banding machine, ensuring a secure bond, no debonding, no bubbling, and waterproofing. The drawer bottom is ≥0.5cm thick, double-faced multi-layer board. (See the reference image below.)

|

23. Desk door: 47cm*42cm*1.8cm (±0.2cm deviation allowed). The panel base is made of environmentally friendly E1-grade medium-density fiberboard (MDF) with a thickness of ≥1.8cm. The surface is tough, non-fracture-resistant, easy-to-clean, moisture-resistant, and non-fading. The drawer is molded with PP injection molding and edge-sealing in one step. The door features stainless steel hinges with the same length as the door. These hinges have a long service life and are not prone to deformation or sag after prolonged use. The door panel has a handle and a keyhole on the left center, a user-friendly design with smooth edges. The lower end of the desk is equipped with a galvanized steel moisture-proof mat with a height of (5.0cm±0.2cm)×(0.12cm±0.01cm); (reference diagram shown below)

|

24.Wardrobe door panels: upper door specifications: 47cm×42cm×1.8cm (allowing a positive or negative deviation of 0.2cm), lower door specifications: 122cm×42cm×1.8cm (allowing a positive or negative deviation of 0.2cm); the base material of the board is environmentally friendly E1 grade medium-density fiberboard with a thickness of ≥1.8m, and the surface is tough, not easy to break, easy to clean, moisture-proof, and does not fade. The door panels are molded in one piece using PP injection molding with edge banding. A handle and keyhole are located in the center of the left side of the door panel, creating a user-friendly design that facilitates opening and closing. The edges are smooth and rounded. Each wardrobe is divided into two levels, the upper level separated by a partition. The lower level features a φ19 stainless steel clothes rail and a single-layer panel. The cabinet body is constructed from 17cm or thicker solid fir core eco-friendly board. PVC edge banding of 0.12cm or thicker is applied using a fully automatic edge banding machine. High-temperature granular hot-melt adhesive ensures a secure, debonding-free, blister-free, and waterproof bond. The back panel is 5cm or thicker, double-faced multi-layer board. The doors feature stainless steel hinges, each the same length as the door itself. These hinges are durable and resist deformation and door sag after prolonged use. The wardrobe bottom uses a galvanized steel moisture-proof mat with a height of (5cm ± 0.2cm) x (0.12cm ± 0.01cm); the wardrobe door panels are of two sizes. The handles are independently injection molded. (See the reference image below)

|

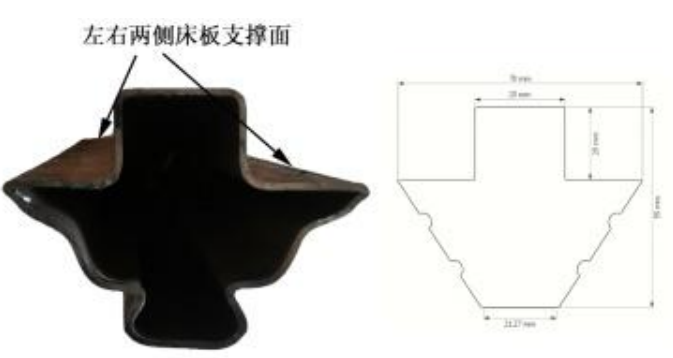

25. The lower support material for the side guardrail is 54mm*49mm (±2mm allowed) steel pipe with a thickness of ≥1.2mm. The steel pipe is designed as the bed support surface to prevent students from stepping on it. To achieve aesthetics, ensure sufficient bending resistance, and increase durability, two concave reinforcement ribs are designed on the outer surface and one concave reinforcement rib on the inner surface (as shown in the figure below):

|

26. The lower support material for the center guardrail is a 70mm*49mm (±2mm allowed) steel pipe with a thickness of 1.2mm. The steel pipe is designed as the bed support surface to prevent students from stepping on it. To achieve aesthetics, ensure sufficient bending resistance, and increase durability, two concave reinforcement ribs are designed on the outer surface and one concave reinforcement rib on the inner surface (as shown in the figure below):

|

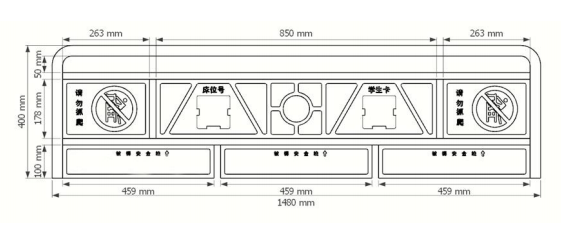

27. The outer main frame of the guardrail is made of 32mm round tube through core bending; the inner support material is made of 31mm*20mm square tube. A protruding reinforcement rib is featured on the outer side to enhance the aesthetics and strength of the tube. The entire closed steel plate is stamped and formed in a single step. The middle plate must be designed with slots (for the school emblem, student card, and bed number). Warning patterns ("Do Not Climb") are placed on the left and right sides, and three panels on the lower side are designed as bedding safety warning lines. Steel plate thickness ≥ 0.6mm (as shown below):

|

|

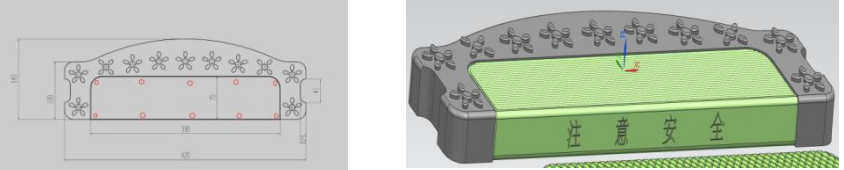

28. Specifications for the student bed step: 420mm ± 2mm long, 135mm ± 2mm wide, and 22mm thick, stamped from 1.5mm steel plate in a single step. The step features an arc-shaped front edge, with 11 plum blossom-shaped decorative patterns on the left, right, and front sides for added aesthetic appeal and grip. The outer edge features a 328mm long and 70mm wide luminous strip. The lower end of the outer (mounting) side of the step is bent again, and the luminous strip wraps from top to bottom, including the bend, to effectively prevent injury to the student. The luminous strip has no fewer than eight buckles and no fewer than 27 raised reinforcing ribs, adding strength and providing anti-slip protection. (As shown in the image below):

|

29. The bed support is made of a 58mm*22mm (±2mm allowed) D-shaped tube with a thickness of 1.0mm. Two concave ribs are designed on each side of the tube to prevent the bed support from hitting the student and to increase its aesthetics and strength (as shown in the figure below):

|

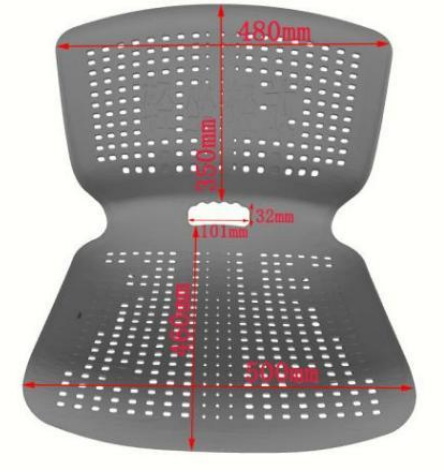

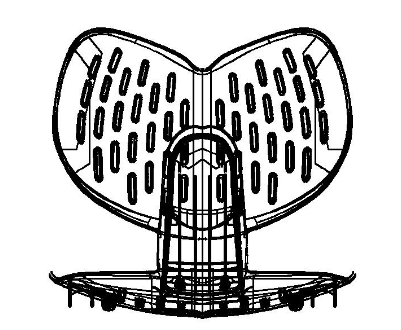

30. One-piece seat and backrest: Made from good quality, environmentally friendly, virgin PP plastic, the chair is modified and then injection-molded in one go. It is impact-resistant, pressure-resistant, and wear-resistant, meeting environmental standards. The one-piece chair features a hollowed-out surface, and the backrest features a curved design that conforms to ergonomics and fits comfortably, small fatigue. A 101mm long x 32mm wide handhold hole is designed at the junction of the backrest and seat. The top of the handhold hole features a wave-shaped design that fits the fingers, enhancing user comfort. To extend the product's lifespan, the back of the handhold hole has five longitudinal and three transverse ribs arranged in a "well" pattern on each side. The seat must be 500mm wide by 445mm deep (from the bottom of the handle hole to the front of the seat), and the backrest must be 480mm wide by 350mm high (from the top of the back of the handle hole to the top of the backrest). The seat surface must have smooth lines, with a wavy and waterfall-like design at the front of the seat cushion. The bottom of the seat must have six screw holes for connecting to the chair frame. The one-piece seat must have elliptical, diverging ventilation holes with a small diameter of 3mm and a big of 14mm, with a small of 480 holes. The top of the backrest must be marked with the words "Be Careful When Sitting and Putting Down" to remind students to respect public property. (Appearance dimension deviations are allowed within ±2mm.)

|

|

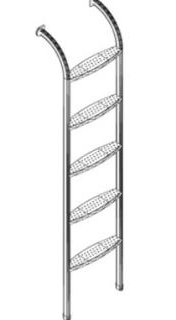

31. Bed ladder: The bracket is made of oval tubing, with a cross-sectional dimension of ≥ 20mm x 40mm and a material thickness of ≥ 1.2mm. The pedal base is stamped from Baosteel cold-rolled steel sheet, with a thickness of ≥ 1.4mm and a vertical dimension of ≥ 420mm x 100mm. The pedals are inlaid with environmentally friendly ABS (acrylonitrile-butadiene-styrene) plastic injection molded for anti-slip properties, with a vertical dimension of ≥ 360mm x 60mm. The 20 x 40 oval tubing must comply with GB/T 3325-2017 "General Technical Requirements for Metal Furniture," QB/T 3827-1999 "Test Methods for Corrosion Resistance of Metal Coatings and Chemically Treated Coatings on Light Industrial Products - Acetic Acid Salt Spray Test (ASS) Method," QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings on Light Industrial Products," and GB/T 1741-2020 "Determination of Fungal Resistance of Paint Films" testing standards, the test content includes at least: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, specified plastic extension strength Rp0.2 ≥ 300MPa.

|

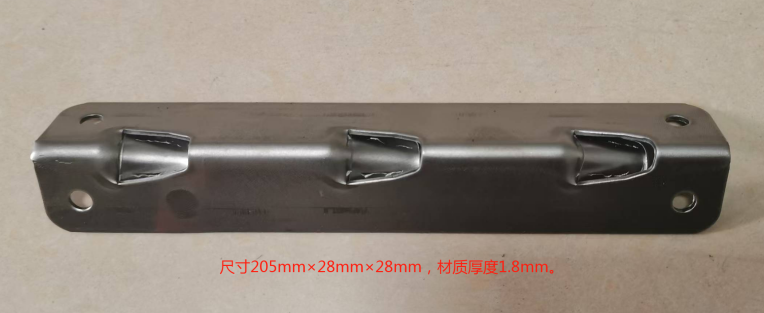

32. Bed hanging connector: Punched into L shape by a punch press, it must have three connecting bayonet sockets. The size after forming is ≥205mm×28mm×28mm, and the material thickness is ≥1.8mm.

|

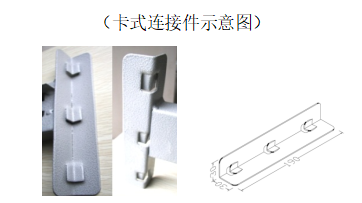

33. Link Buckle: This pressure-fastening "clip-on connector" is stamped from high-quality steel plate in one step. It is stamped from 2.0mm thick cold-rolled steel plate. Dimensions are 30mm (±2mm) x 30mm (±2mm) x 190mm (±2mm). Installation method: "H"-shaped clip-on connection. The clips are connected at no fewer than three points and have latches. Pressing down with the clip-on connector ensures a tighter fit. This design complies with the technical requirements of GB/T 3325-2017. The metal spray (plastic) coating has a physical and chemical performance hardness of ≥4H.

|

34. Bed columns: Made of high-quality carbon steel plates rolled into tubes (square tubes cannot be used for open types), double-sided paint spraying, and with a convex reinforcement rib with a radius of 12mm on three sides of the column. Specifications: length 85mm * width 72.5mm * wall thickness 1.2mm. Open-type high-quality special-shaped material, the connector is flush with the column, and the overall appearance is beautiful. The pipe must be rolled into shape in one step, and hammering is not allowed, and splicing is invalid (the external dimension deviation range is ±2mm, and the material thickness does not allow negative deviation). Bed columns should comply with GB/T 1741-2020 "Determination of mildew resistance of paint films", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", and QB/T 3827-1999 "Corrosion resistance test method of metal coatings and chemical treatment layers on light industrial products The testing standards for the "Acetic Acid Salt Spray Test (ASS) Method" include at least the following: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungus resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, and adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, and specified plastic extension strength Rp0.2 ≥ 300MPa.

|

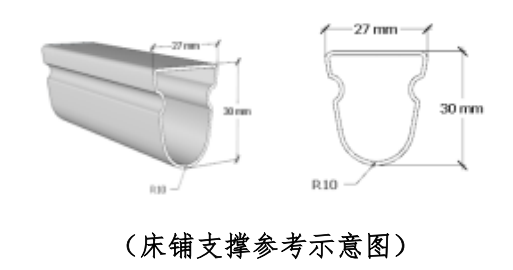

35. Bed Support: High-frequency closed-end special-shaped tubing is used (open profiles and square tubing are not acceptable). Specifications: 27mm*30mm*0.9mm (Appearance dimensional deviation is ±2mm, material thickness is not allowed to deviate negatively). The sides of the supports feature concave R3 arc-shaped reinforcement ribs for increased toughness, and the bottom features an R10 arc treatment to prevent students from bumping. The top has a straight edge, 27mm wide, for increased strength and safety. Impact resistance is negligible. Five ribs are used per bed. (Appearance dimensional deviation is ±2mm, material thickness is not allowed to deviate negatively).

|

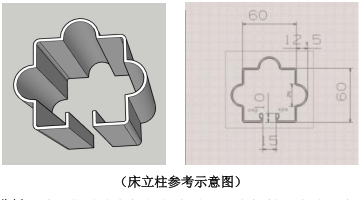

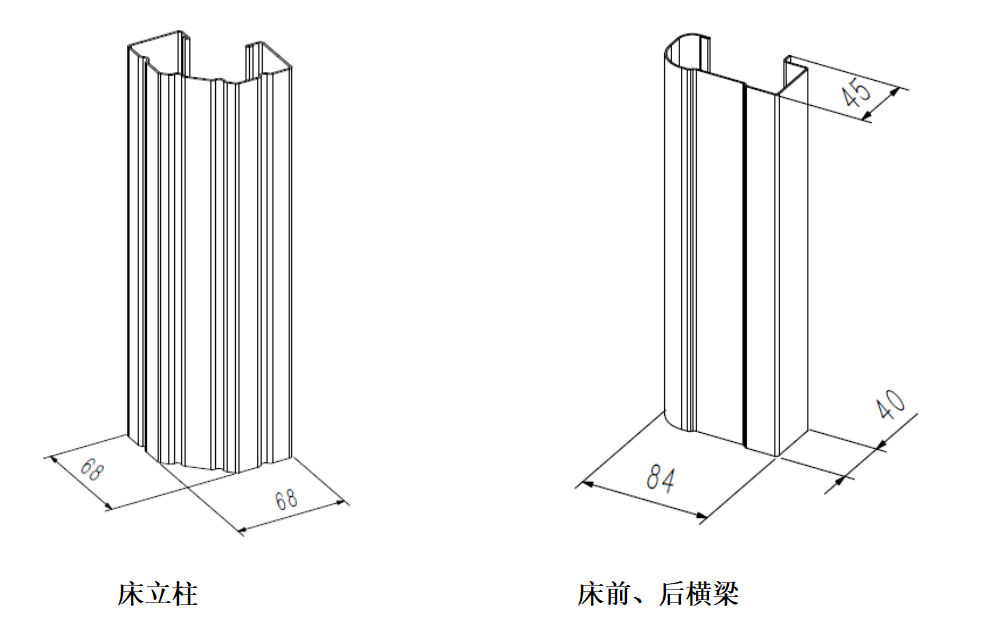

36. Bed Support: High-frequency closed-end special-shaped tubing is used (open profiles and square tubing are not acceptable). Specifications: 27mm*30mm*0.9mm (appearance dimension deviation is ±2mm, and negative deviation is not permitted for material thickness). The sides of the supports feature concave R3 arc-shaped reinforcement ribs for increased toughness. The bottom of the supports feature R10 arc treatment to prevent students from bumping into them. The top has a straight edge, 27mm wide, providing overall strength and safety. Impact is ineffective. Five ribs are used per person. (The deviation range of the external dimensions is allowed to be ±2mm, and the material thickness does not allow negative deviation) 36. Bed columns: Use high-quality rolled steel plates to be rolled into open profiles by a forming machine in one time (closed tubes cannot be used) so that the product can be sprayed on both sides inside and outside. The vertical size after forming is 68mm*68mm, the thickness is 1.3mm, and the inner side edges are pressed dead (to prevent cuts to the hands). The column has 4 inward concave reinforcement ribs as a whole. (The deviation range of the external dimensions is allowed to be ±2mm, and the material thickness does not allow negative deviation); the bed columns should comply with GB/T 1741-2020 "Determination of mildew resistance of paint films", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", and QB/T 3827-1999 "Corrosion resistance test method of metal coatings and chemical treatment layers of light industrial products The testing standards for the "Acetic Acid Salt Spray Test (ASS) Method" include at least the following: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungus resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metal spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, and adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, and specified plastic extension strength Rp0.2 ≥ 300MPa. Front and rear crossbeams and upper short crossbeams: Use high-quality rolled steel plates to form open profiles through a forming machine. The bottom of the profile is arc-shaped (to prevent head injury) and the top is flat (closed tubes cannot be used) so that the product can be sprayed on both sides. The vertical size after forming is 84mm*40mm and the thickness is 1.4mm. The surface of the front and rear crossbeams must have two inward concave reinforcement ribs or use a one-time stamping pattern with a mold to increase strength and appearance (the bed crossbeams should comply with GB/T 1741-2020 "Determination of mildew resistance of paint films", QB/T 3832-1999 "Evaluation of corrosion test results of metal coatings on light industrial products", QB/T 3827-1999 "Corrosion resistance test method of metal coatings and chemical treatment layers of light industrial products The testing standards for the "Acetic Acid Salt Spray Test (ASS) Method" include at least the following: acetic acid salt spray test (≥1200h): corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata): level 0 or 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metallic spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, and specified plastic extension strength Rp0.2 ≥ 300MPa. The external dimensions are allowed to deviate by ±4mm, and negative deviation of material thickness is not allowed.

|

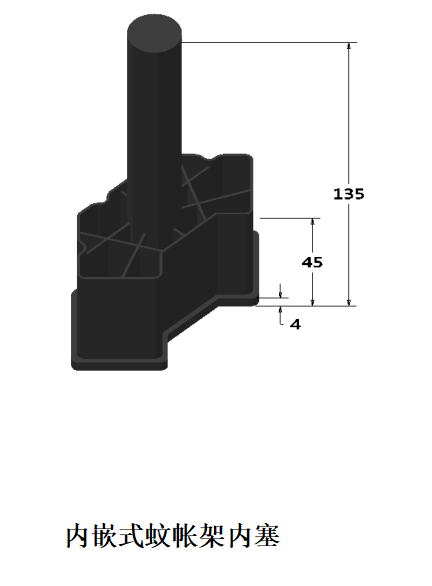

37. Plug the foot covers into the mosquito net frame: Use high-quality new plastic material with a length of at least 45mm, and the insertion depth of the mosquito net pole should be at least 135mm to prevent the mosquito net pole from loosening. Foot covers must comply with GB/T 32487-2016, GB/T 31402-2023, GB/T24128-2018, GB/T3398.2-2008, GB/T9341-2008, GB/T14153-1993, GB/T1043.1-2008, GB/T1633-2000, and GB/T22048-2022. Inspection and testing items include, but are not limited to: Plastic parts must be free of cracks, significant deformation, shrinkage, pinholes, dents, flash, wrinkles, bumps, bubbles, impurities, scars, or white marks. The surface must be smooth and free of scratches, burrs, lint, stains, or significant color difference. Impact strength must be ≥2000J/㎡. Thermal cycling resistance: There must be no cracks, blistering, discoloration, or wrinkling. Shore Hardness: ≥ HD70. Antibacterial Performance - Staphylococcus aureus: Antibacterial Rate ≥ 99.9%. Mold Resistance - Aspergillus niger and Geotrichum candidum: No growth at Grade 0. Rockwell Hardness ≥ 65. Flexural Properties - Flexural Strength ≥ 40 MPa. Flexural Modulus of Elasticity: Meets requirements. Drop Hammer Impact Test (Drop Hammer Mass: 0.5 kg, Impact Height: 1000 mm). Charpy Impact Test: ≥ 6.5. Vicat Softening Temperature ≥ 72.4°C, Meets requirements. Phthalate Plasticizers Not Detected.

|

38. Side columns: The external specifications of the columns are 60 (±2) mm*70 (±2) mm with a thickness of not less than 1.2 mm. The pipes are made of high-quality strip steel, rolled into shape by a rolling line, and high-frequency welded into closed P-type pipes. The front is designed to be curved, and the sides are connected to the bed and hall hangers with no less than three points of contact. It complies with the technical requirements of GB/T 3325-2017, GB/T 228.1-2021, GB/T 6725-2017, and GB/T708-2019. The mechanical properties are tensile strength ≥600 MPa, the physical and chemical properties of the metal spray (plastic) coating are hardness ≥5H, the corrosion resistance is qualified, the adhesion is not less than level 2, and four soluble heavy metals are not detected. Both upper and lower columns utilize high-quality PP plastic silent plugs, meeting the technical requirements of GB 28481-2012, GB/T 32487-2016, and GB/T31402-2015. The plastic material has passed aging resistance and thermal cycling tests, with no detectable levels of heavy metals or phthalates. The antibacterial rate against Staphylococcus aureus, Klebsiella pneumoniae, and Escherichia coli is at least 99%.

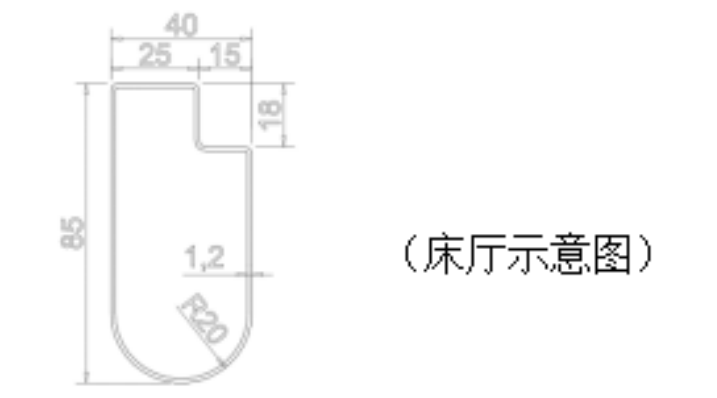

(Bedroom diagram:)

|

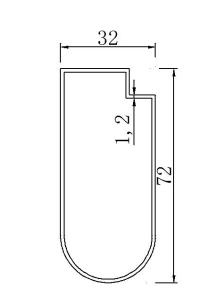

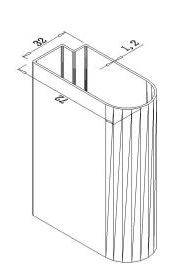

39. Front and Rear Hallways: The front hallway profile specifications are 80 (±2) mm * 30 (±2) mm, with a thickness of no less than 1.2 mm; the rear hallway profile specifications are 72 (±2) mm * 32 (±2) mm, with a thickness of no less than 1.2 mm. The tubing is made of high-quality strip steel, roll-formed using a rolling mill, and high-frequency welded into closed-end profile tubes. The hallways comply with the technical requirements of GB/T 3325-2017, GB/T 228.1-2021, GB/T 6725-2017, and GB/T 708-2019. Mechanical properties of the hallways include a tensile strength of ≥ 500 MPa, a hardness of ≥ 5H for the metal spray (plastic) coating, corrosion resistance, adhesion of no less than Grade 2, and qualified soluble heavy metal testing in the coating and cladding.

(Note: Column heads of varying sizes may exist in the rooms; bidders must consider this based on the drawings or actual site conditions.)

(Front Hall Schematic Diagram:) (Rear Hall Schematic Diagram:)

| (Front Hall Schematic Diagram:) | (Rear Hall Schematic Diagram:) | ||

|

|

|

|

40. Uprights: 85×85×40×62×40 (±1mm)×1.2mm shaped five-sided tubes are used, with concave reinforcement ribs on both sides of the front. The profile design effectively increases the usable space of the bed, and the front is designed without sharp corners, which can effectively reduce the physical damage caused by accidental slips. (Profile molding method: cold plate mechanical stretching and folding molding) The upper and lower columns are made of high-quality PP plastic silent plugs, which are stable, no shaking, no abnormal noise, and safe protection. See the schematic diagram for details:

|

41. Bed hall: The bed hall adopts 85mm×40mm (±1mm) high-frequency welded sealed profile pipe with a wall thickness of 1.2mm. The overall structure is stable and beautiful, and is equipped with PP plastic rubber sleeve to prevent moisture.

|

42. Bed Replacement: 30 (±2) mm x 20 (±2) mm rectangular tubes with a thickness of no less than 1.2 mm are used, with no fewer than seven bed replacements designed at each end. ABS engineering plastic sound-absorbing and anti-collision rubber sleeves are installed at the hanging joints to ensure a stable and aesthetically pleasing connection between the bed replacement and the bed hall, while also eliminating steel frame noise caused by external forces. A center bed replacement limiter prevents the bed replacement from falling. Bed replacements must comply with the technical requirements of GB/T 3325-2017, GB/T 228.1-2021, GB/T 6725-2017, and GB/T 708-2019. Soluble heavy metals in the coating and covering layers must pass testing. The metal spray (plastic) coating must meet physical and chemical performance requirements, including a hardness of 5H or higher, corrosion resistance of no rust, shedding, or peeling within 100 hours, adhesion of no less than Class 2, and qualified testing for soluble heavy metals in the coating and covering layers. Mechanical properties include a tensile strength of 500 MPa or higher, and a lower yield strength of 400 MPa or higher.

(Bed replacement diagram:)

|

|

|

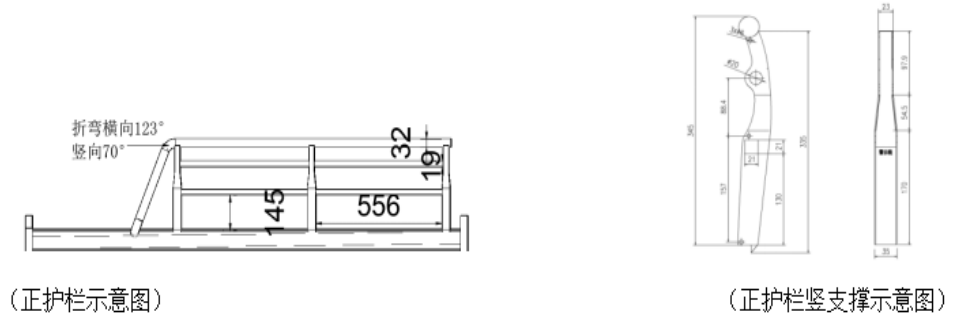

43. Bedside Guardrails: The outer frame dimensions must be no less than 1300mm x 350mm x 25mm. The main guardrail frame is constructed from high-quality 25mm x 1.2mm cold-rolled steel pipe, bent in a single step using a CNC machine. The vertical supports are welded from φ19mm round tube and 20mm square tube. A hollow blow-molded baffle, measuring no less than 1250mm x 160mm x 20mm, is installed beneath the guardrail. Made of HDPE (high-density polyethylene), the baffle features a hollow blow-molded process. The left and right sides have movable observation ports that can be opened or closed, facilitating observation by dormitory staff while ensuring student privacy. The hollow blow-molded guardrails comply with the technical requirements of GB 28481-2012 and have passed heavy metal content testing. A card with the school emblem and student information can be placed in the center of the guardrail. The rear of the baffle features a big mattress thickness indicator and a permanent safety warning line. The guardrail height must be ≥350mm, meeting the standard dimensions for bed safety guardrails. (Schematic diagram of the front hall guardrail:)

|

44. Ladder: The ladder side tubes are constructed of oval tubing no less than φ32mm x 1.0mm thick, with at least five steel footboards measuring 370 (±2) mm x 90 (±2) mm and no less than 2.0 mm thick. They are formed from cold-rolled steel sheet by bending and die-casting in a single pass. The footboards are securely welded to the uprights and feature no fewer than 60 anti-slip bumps. The footboards are designed with embedded luminous strips (which do not come into contact with the body, making them more environmentally friendly) for added safety. The footboards are securely welded to the uprights. Rubber Sleeves at Ladder Connections: The ladder connects to the bed hall with tension screws, and exposed screws are covered with rubber sleeves for aesthetic appeal and to prevent oxidation and rust. Special PP plastic sleeves are installed at the ends of the steel pipes that contact the ground. This prevents the steel pipes from directly contacting the ground, ensuring moisture and corrosion resistance, durability, aesthetics, safety, and comfort. The ladder complies with the technical requirements of GB/T10125-2021 "Artificial Atmosphere Corrosion Test - Salt Spray Test" and GB/T3325-2017 "General Technical Requirements for Metal Furniture." The ladder, footrests, and accessories meet the required standards for stable deflection and strength. The footrests exhibit no damage, peeling, cracking, deformation, or loosening when subjected to impact, achieving a corrosion resistance rating of 10. The metal plastic spray coating has a hardness of ≥5H, adhesion of no less than Grade 2, and passes soluble heavy metal testing.

(Ladder Diagram:) (Ladder Footrest Diagram:)

|

|

|

45. Apartment Chair/Steel-Plastic Chair/Study Chair

(See diagram:)

|

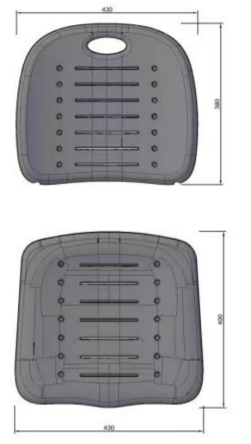

Specifications: 430 (±2) mm * 450 (±2) mm * 440/800 (±2) mm; Steel Frame: Constructed of welded egg-shaped tubes measuring no less than 30 (±2) * 25 (±2) mm and φ16 mm round tubes, with a wall thickness of no less than 1.2 mm, ensuring overall stability and aesthetics. Seat and Back Panel: The seat measures 430 mm (±2 mm) wide by 450 mm (±2 mm) deep, with a wavy front and long ventilation holes in the middle for a comfortable and breathable feel. The backrest measures 410 mm (±2 mm) wide by 395 mm (±2 mm) high, with a curved, wrap-around design and built-in handles on both sides. Chair seat and back: Crafted entirely from environmentally friendly, good quality PP plastic, the chair is injection-molded in a single pass after modification and improvement. It exhibits no noticeable deformation, bubbles, or impurities, and complies with the technical requirements of GB 28481-2012, GB 20286-2006, GB/T 31402-2015, and GB/T 32487-2016. The plastic material has passed inspection for flame retardancy, combustion performance, antibacterial rate, aging resistance, and thermal cycling resistance. No heavy metals or phthalates were detected. Product Performance: The one-piece chair features a hollowed-out surface, and the seat and back panels are designed with a number of custom-designed strip ventilation holes. Both the seat and backrest feature a curved, wrap-around design for ergonomic comfort. The front end of the seat cushion must have a wavy and waterfall-shaped design, and the back of the seat must have no fewer than six crisscrossing reinforcement ribs. The backrest has a 10-30° swing back, which can relieve students' waist fatigue, effectively correct their sitting posture, and provide a comfortable sitting experience. No fewer than four embedded nuts are designed under the seat panel to make the connection between the steel frame and the back panel more secure. The chair meets the technical requirements of GB/T3324-2017 and GB28481-2012, and has passed the soluble heavy metal content test. The combined durability of the seat and chair surface has passed 100,000 tests. The metal spray coating has a hardness of ≥5H, no peeling, cracking, or wrinkling at an impact height of 400mm, and is corrosion-resistant with no bubbling, rust, discoloration, or loss of gloss within 100 hours. It has aging resistance with a discoloration rating of ≥3 for no less than 400 hours. It is impact-resistant, pressure-resistant, and wear-resistant, with no obvious deformation, bubbles, or impurities. The thermosetting powder coatings used should comply with the testing standards of HG/T2006-2006 "Thermosetting Powder Coatings". The testing contents should at least include: hardness (scratch) ≥H, moisture and heat resistance (no abnormality for 500h), adhesion level 0, impact resistance should be free of cracks, wrinkles and peeling, alkali resistance (5% NaOH) no abnormality for 168h, acid resistance (3% HC1) no abnormality for 240h, boiling water resistance no abnormality for 2h; heavy metals (soluble mercury ≤5mg/kg, soluble cadmium ≤5mg/kg, soluble chromium ≤5mg/kg, soluble lead ≤5mg/kg). 16 Round tubes should comply with GB/T 3325-2017 "General Technical Requirements for Metal Furniture", QB/T 3827-1999 "Test Methods for Corrosion Resistance of Metal Coatings and Chemically Treated Coatings on Light Industrial Products - Acetic Acid Salt Spray Test (ASS)", QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings on Light Industrial Products", GB/T The testing standard 1741-2020, "Determination of Mold Resistance of Paint Films," requires at least the following: acetic acid salt spray test (≥1200h): Corrosion Resistance Grade 10, Protection Grade 10; Mold Resistance Grade (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata): Grade 0 or 1; Soluble heavy metals in coating: Soluble lead ≤ 5 mg/kg, Soluble mercury ≤ 5 mg/kg, Soluble chromium ≤ 5 mg/kg, Soluble cadmium ≤ 5 mg/kg; Metallic spray paint (plastic) coating: Hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, Adhesion Grade 0; Tensile test: Tensile strength Rm ≥ 300 MPa, Elongation after fracture A50mm ≤ 35%, and Specified plastic extension strength Rp0.2 ≥ 300 MPa.

(Reference diagram of one-piece seat back panel:)

|

|

46. Main Guardrail: To ensure safety, the entire structure is constructed of steel and wood. The guardrail height is ≥340mm; the length is ≥1400mm. The safety vertical supports are made of 1.5mm thick, high-quality cold-rolled steel plate formed through CNC stamping and stretching. The rear opening is seamlessly connected with high-quality PP plastic components (with safety warning lines). The lower section features a ≥16mm thick cover plate (based on E0-grade environmentally friendly particleboard with a melamine finish) to block lint and maintain a neat appearance. The top of the guardrail is constructed of Φ32mm round tube, and the middle pipe is Φ19mm x 1.0mm round tube. (This complies with national safety guardrail standards. The steel frame is fully welded to the bedside hallway for increased strength and safety.)

Headrail: Length 770mm (±2mm) * Thickness 30mm (±2mm) * Height 430mm (±2mm). The base material is 18mm thick, E0-grade, environmentally friendly particleboard with a melamine finish. The entire structure is constructed using a one-step steel-wood-plastic injection molding process, ensuring waterproof, moisture-proof, wear-resistant, and scratch-resistant construction. The top of the guardrail features a 30mm diameter round tube encased in a 10mm thick soft wrapping material. The tube and board are integrally formed using an injection molding process, creating seamless joints. The guardrail connects to the bed support with a plug-in design, ensuring load-bearing capacity and safety, and features a permanent safety warning line.

|

47. Study chair material parameter description: Specifications: front seat width 430mm (±2mm) × seat depth 400mm (±2mm) × chair height 850mm (±2mm) Material and requirements: Chair frame uses 30*15mm oval steel pipe, wall thickness 1.2mm; Steel pipe welding requirements; Steel pipe painting requirements: Shot blasting and rust removal, epoxy polyester solid powder high-voltage electrostatic spraying; The exposed ends of the steel pipe are all equipped with special plastic covers; The seat and back panels should be made of virgin HDPE hollow blow molding, double-layer, more durable and comfortable; Seat panel size: front width 430mm (±2mm), seat panel depth 400mm (±2mm); Back panel size: width 430mm (±2mm), height 380mm (±2mm); thickness ≥20mm; the seat and back panels are designed with ≥7 strip-shaped ventilation holes, and the curved design is ergonomic. The backrest fits the back, making sitting comfortable and not prone to fatigue; the back panel is designed with a handle position; the back of the seat back panel is equipped with embedded nuts, and the steel frame is firmly connected to the seat back panel.

|

|

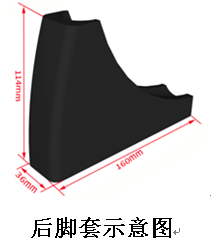

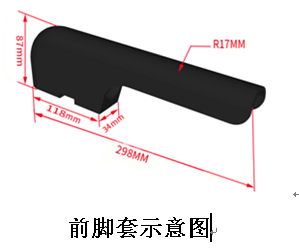

48. Foot covers: Made of PP plastic, one-time injection molding. The front foot cover dimensions are 298mm long, 87mm high, and 34mm wide (±2mm). The rear foot cover dimensions are 160mm long, 36mm high, and 114mm wide (±2mm). Foot covers must comply with GB/T 32487-2016, GB/T 31402-2023, GB/T24128-2018, GB/T3398.2-2008, GB/T9341-2008, GB/T14153-1993, GB/T1043.1-2008, GB/T1633-2000, and GB/T22048-2022. Inspection and testing items include, but are not limited to: Plastic parts must be free of cracks, significant deformation, shrinkage, pinholes, dents, flash, wrinkles, bumps, bubbles, impurities, scars, or white marks. The surface must be smooth and free of scratches, burrs, lint, stains, or significant color difference. Impact strength must be ≥2000J/㎡. Thermal cycling resistance: There must be no cracks, blistering, discoloration, or wrinkling. Shore Hardness: ≥ HD70. Antibacterial Performance - Staphylococcus aureus: Antibacterial Rate ≥ 99.9%. Mold Resistance - Aspergillus niger and Geotrichum candidum: No growth at Grade 0. Rockwell Hardness ≥ 65. Flexural Properties - Flexural Strength ≥ 40 MPa. Flexural Modulus of Elasticity: Meets requirements. Drop Hammer Impact Test (Drop Hammer Mass: 0.5 kg, Impact Height: 1000 mm). Charpy Impact Test: ≥ 6.5. Vicat Softening Temperature ≥ 72.4°C, Meets requirements. Phthalate Plasticizers Not Detected.

|

|

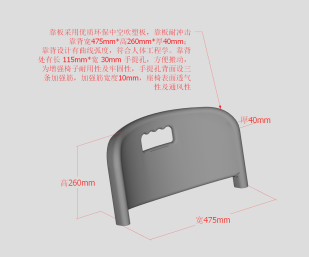

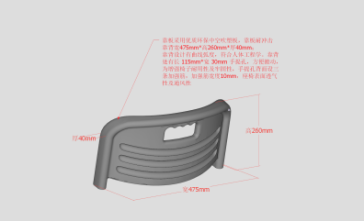

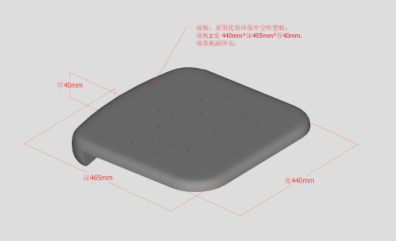

49. Seat and Back: Made of environmentally friendly hollow blow-molded board, the seat measures ≥440mm wide, 465mm deep, and 40mm thick; the backrest measures ≥475mm wide, 260mm high, and 40mm thick. The seat and back are impact-, pressure-, and wear-resistant, meeting environmental requirements. The one-piece seat and back are hollowed out, and the backrest features a curved design for ergonomic comfort. The backrest features a ≥115mm long, 30mm wide carry hole for easy transport. To enhance the chair's durability and strength, three 10mm-wide reinforcing ribs are located behind the carry hole. The seat surface is breathable and ventilated. Hollow blow molded panels comply with the standards including but not limited to GB/T 32487-2016 "General Technical Conditions for Plastic Furniture" and "Limits of Hazardous Substances in Plastic Furniture": 1. Appearance of plastic parts: no cracks, no obvious deformation, no shrinkage, no pinholes, no dents, no burrs, no wrinkles, no lumps, no bubbles, no impurities, no scars, no white marks, smooth surface, no scratches, no burrs, no fuzz, no stains, no obvious color difference; 2. Resistance of plastic parts to hot and cold cycles: no cracks, no bubbling, no discoloration, no wrinkles; 3. Heavy metals: soluble lead ≤0.5mg/kg, soluble cadmium ≤0.5mg/kg, soluble chromium ≤0.5mg/kg; soluble mercury ≤0.5mg/kg.

|

|

|

|

50. Apartment Chair: Dimensions are 440mm*465mm*760mm (length*width*height), with a tolerance of plus or minus 5mm. Seat and backrest: Made of environmentally friendly hollow blow-molded board. Seat measures ≥440mm wide, 465mm deep, and 40mm thick; backrest measures ≥475mm wide, 260mm high, and 40mm thick. The seat and backrest are impact-resistant, pressure-resistant, and wear-resistant, meeting environmental standards. The integrated seat and backrest feature a hollowed-out surface, and the backrest is curved for ergonomic comfort. The backrest has a carry hole measuring ≥115mm long and 30mm wide for easy transport. To enhance the chair's durability and strength, three reinforcing ribs ≥10mm wide are located behind the carry hole. The seat surface is breathable and ventilated. Hollow blow molded panels comply with the standards including but not limited to GB/T 32487-2016 "General Technical Conditions for Plastic Furniture": 1. Appearance of plastic parts: no cracks, no obvious deformation, no shrinkage, no pinholes, no dents, no burrs, no wrinkles, no lumps, no bubbles, no impurities, no scars, no white marks, smooth surface, no scratches, no burrs, no hairs, no stains, no obvious color difference; 2. Resistance of plastic parts to hot and cold cycles: no cracks, no bubbles, no discoloration, no wrinkles; 3. Heavy metals: soluble lead ≤0.5mg/kg, soluble cadmium ≤0.5mg/kg, soluble chromium ≤0.5mg/kg; soluble mercury ≤0.5mg/kg. Chair frame: The chair legs are made of 20mm*40mm oval steel tubes with a thickness of 1.2mm, and the crossbars are made of 20mm*40mm oval tubes with a thickness of 1.2mm; Foot covers: The chair legs are made of plastic foot covers with anti-slip inner plugs; the 20*40 oval tubes should comply with GB/T 3325-2017 "General Technical Conditions for Metal Furniture", QB/T 3827-1999 "Test Method for Corrosion Resistance of Metal Coatings and Chemically Treated Layers on Light Industrial Products - Acetic Acid Salt Spray Test (ASS) Method", QB/T 3832-1999 "Evaluation of Corrosion Test Results of Metal Coatings on Light Industrial Products", GB/T 1741-2020 "Determination of Fungal Resistance of Paint Films" standard, the test content at least includes: acetic acid salt spray test (≥1200h) corrosion resistance level 10, protection level 10; fungal resistance level (Aspergillus niger, Aspergillus flavus, Cladosporium herbarium, Paecilomyces variotii, Penicillium citrinum, Trichoderma viride, Aureobasidium pullulans, Alternaria alternata) level 0 or level 1; soluble heavy metals in the coating: soluble lead ≤ 5mg/kg, soluble mercury ≤ 5mg/kg, soluble chromium ≤ 5mg/kg, soluble cadmium ≤ 5mg/kg; metallic spray paint (plastic) coating: hardness ≥ 4H, no peeling, cracking, or wrinkling at an impact height of 400mm, adhesion level 0; tensile test: tensile strength Rm ≥ 300MPa, elongation after fracture A50mm ≤ 35%, specified plastic extension strength Rp0.2 ≥ 300MPa. Process Requirements: Steel welding shall be conducted using CO2 gas shielded welding. Welds shall be free of misalignment, desoldering, cold joints, or defects. Steel components shall be treated with ceramic, shot blasting, and electrostatic powder coating. The coating on metal parts shall be free of spray gaps and rust; the coating shall be smooth, uniform, and of uniform color, free of defects such as sags, bumps, wrinkles, or paint spalling. Thermosetting powder coatings shall comply with the HG/T2006-2006 "Thermosetting Powder Coatings" standard. Testing shall include at least: hardness (scratch) ≥ H, moisture and heat resistance (no abnormalities after 500 hours), adhesion level 0, impact resistance (no cracks, wrinkles, or flaking), alkali resistance (5% NaOH) for 168 hours, acid resistance (3% HCl) for 240 hours, and boiling water resistance for 2 hours; and heavy metal content (soluble mercury ≤ 5 mg/kg, soluble cadmium ≤ 5 mg/kg, soluble chromium ≤ 5 mg/kg, and soluble lead ≤ 5 mg/kg).

|

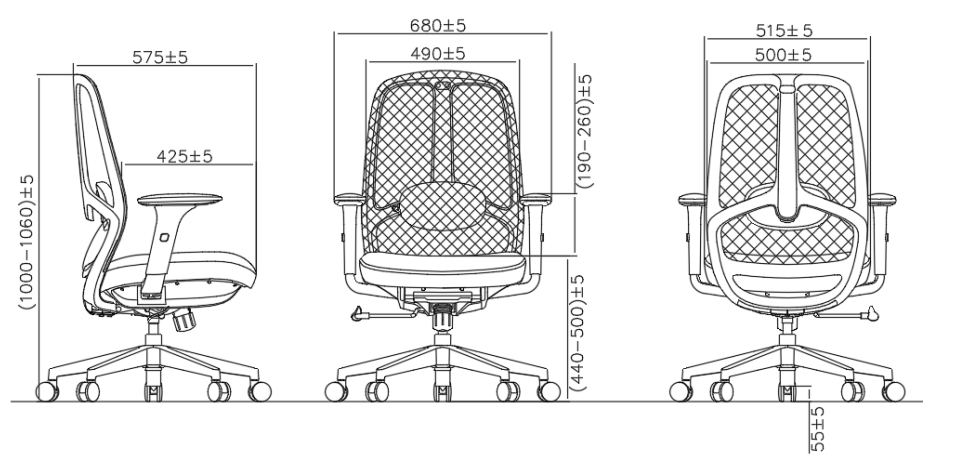

51. Apartment Chair: 680*575*(1000-1060)mm. Apartment chairs must comply with: GB/T3325-2017, GB/T 35607-2017, QB/T 3832-1999, QB/T 3826-1999, QB/T 3827-1999, QB/T 3828-1999, QB/T4371-2012, GB/T1741-2020, GB/T 15596-2021, GB/T 11345-2023. Inspection and testing items include but are not limited to: Physical and chemical properties of metal surface paint (plastic) coatings - Pencil hardness (H): No plastic deformation and/or cohesive failure. Physical and Chemical Properties of Paint (Plastic) Coatings on Metal Surfaces - Impact Strength: No peeling, cracking, or wrinkling at an impact height of 400mm. Physical and Chemical Properties of Paint (Plastic) Coatings on Metal Surfaces - Adhesion: No less than Class 1. Physical and Chemical Properties of Paint (Plastic) Coatings on Metal Surfaces - Salt Bath Resistance: No bubbling, rust, flaking, or wrinkling beyond 3mm on either side of the scratch. Formaldehyde Emission: ≤0.04mg/m³ after 120h of Neutral Salt Spray (NSS), 120h of Acetic Salt Spray (ASS), and 120h of Copper Salt Accelerated Acetic Salt Spray (CASS). The coating's inherent corrosion resistance is Class 10; the coating's protection level for the substrate is Class 10. Physical and Chemical Properties of Coatings on Wood Surfaces - Liquid Resistance: No less than Class 3. Temperature Difference Resistance: No bubbling, cracking, or noticeable gloss loss. Impact Resistance: No less than Class 3. Abrasion Resistance: No less than Class 3. Antibacterial Performance - Serratia marcescens: Inhibition rate ≥ 99.9%. Mold Resistance - Alternaria, Penicillium citrinum: Mold resistance level 0, no growth. Natural aging for 500 hours: No noticeable powdering. Weld Grade: Welds meet Class B non-destructive testing.

|